- #Fusion 360 vs solidworks how to#

- #Fusion 360 vs solidworks mac os#

- #Fusion 360 vs solidworks software#

- #Fusion 360 vs solidworks Pc#

It incorporates both direct and parametric control. Data management is built into Fusion.Īutodesk Fusion has a single model environment in which all unique parts and assemblies can be created.

#Fusion 360 vs solidworks Pc#

As the app can run either on PC or on the cloud, it can work both with and without internet connection.

It is a collaborative platform where users can access each other’s files which shortens the design lifecycle. It is mostly used by students of manufacturing and design spheres for online 3D Printing services.

#Fusion 360 vs solidworks mac os#

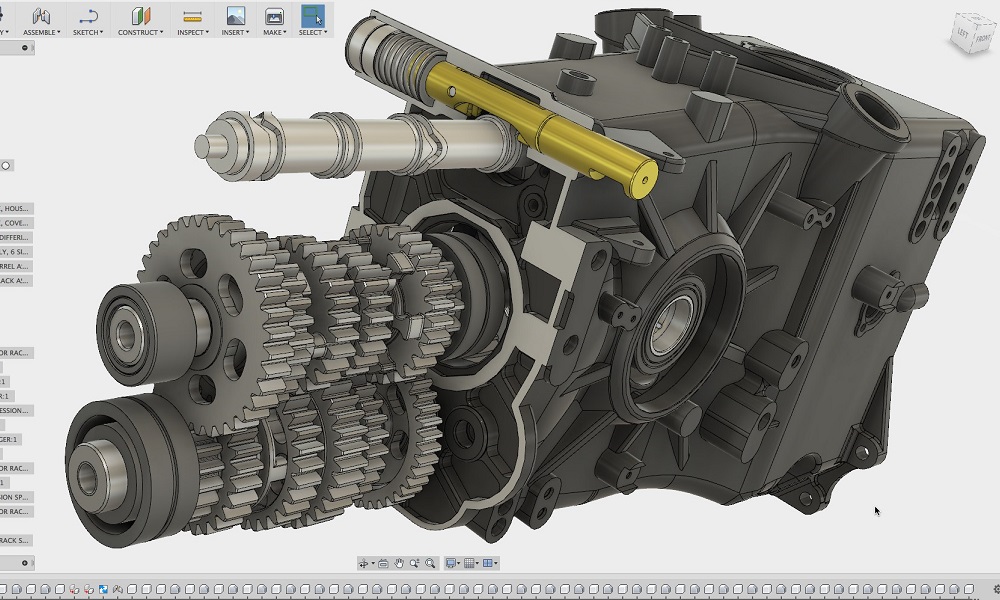

Fusion 360 runs on Windows, Mac OS and in browsers. Solid, Surface, T-Spline and Mesh geometry are supported as well as drawing, rendering and 3D-printed output for design validation and documentation. Fusion 360įusion 360 is a 3D CAD, CAM, CAE cloud-based platform by Autodesk, which connects the development processes of a product. SOLIDWORKS users are capable of drawing 2D and 3D sketches, creating models and assemblies, adding notes, dimensions and tolerances. SOLIDWORKS 'user base covers a very wide range of manufacturing market segments, such as aerospace, transportation, electronics, machinery, medical, etc. SOLIDWORKS is a modeling CAD and CAE program by Dassault Systems which runs on Windows.

#Fusion 360 vs solidworks software#

SolidWorks has always been the leader in the industry for CAD modelling but Fusion 360 launched recently which is the new and cloud-based CAD modelling software which challenges this industrial leader. It depends on your background whether you are an Engineer or designer or architect or a maker to find yourself referring one over the other for 3D Printing online. Fusion 360 also has simulation tools, they are quite basic, but easy-to-use.Fusion 360 vs SolidWorks - b oth the software is used for the same thing, that is 3D modelling. It will allow you to evaluate linear and non-linear responses, composite materials, or dynamics. If you are looking for software with advanced simulation and analysis features, you will have to choose SolidWorks. Fusion 360 offers a wide range of preset construction geometry, which makes it really simple to create all the basic shapes.īut SolidWorks also has some advantages Fusion 360 doesn’t have. SolidWorks is also offering functional tools, but no sculpt-mode and some process are appearing to be a little time-consuming. Fusion 360 is also offering nice sculpt features to start mesh modeling really easily. Moreover, this software developed by Autodesk is really flexible and a bit easier to use, with a great push/pull tool allowing to create great organic geometry and surfaces. Fusion 360 is cloud-based software, combining parametric, surface, freeform direct, and mesh modeling features.įusion 360 has a really complete suite of 3D modeling tools, making it quite easy to create solid models.Solidworks is really targetting experienced users. SolidWorks is a parametric modeling software offering great features for professionals looking for an assembly-oriented program.Some CAD tools can be more needed in some sectors, SolidWorks can be the perfect solution for some 3D modeling users, while Fusion 360 will totally match the needs of other users. But product designers and mechanical engineering students won’t need the same features and will use the program differently, that is a fact.

Solidworks and Fusion 360 are two really good programs, no doubt about it. What editing tools do you need? Which software is offering cloud storage? You will have to choose a program that will suit your project and design process.įor example, architects, engineers, and designers don’t have the same needs when it comes to CAD modeling.

#Fusion 360 vs solidworks how to#

How to choose between CAD modeling software? We know that choosing the right 3D CAD software can be a complex process.

0 kommentar(er)

0 kommentar(er)